|

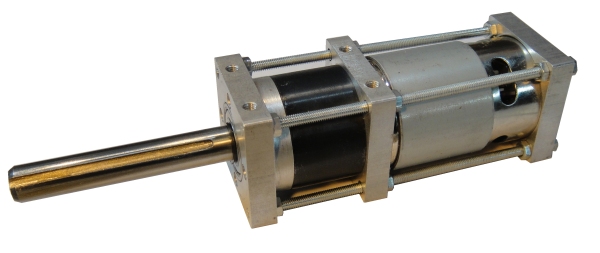

Robot Power Magnum775 gearmotor

The Robot Power Magnum775 is a robust low-cost gearmotor which includes the planetary gearbox and

a powerful RS775 motor. The gearbox output shaft is 0.5" diameter

and 3" long with a precut keyway for easy mounting of wheels and sprockets.

Gearmotor

Specifications:

- Size: 1.75" square

flange x 4.92" long (excluding shaft)

- Weight: 28oz motor and

gearbox

- Motor: Leshi LS-775PX (Mabuchi RS-775 copy)

- Motor voltage: 14.4V

nominal, may be run at 18V

- Gear Ratio: 20:1

2-stage planetary

- Output Shaft:

0.50" dia. x 3.0" long with standard 1/8" keyway

- Gears: machined steel

- Output Bearings: dual

ball bearings

Performance with

stock motor

- Peak Ouput Power: 400W at 14.4V (650W at 18V) motor

spec

- Gearbox output Speed:

720 RPM at 14.4V (KV = 50 RPM/V)

- Gearbox torque

(estimated): Kt = .12Nm/A - 17.0oz-in/A at peak power out 14.4V

- Gearbox stall

torque(theoretical): 17.6Nm - 2500 oz-in

- Motor current: 3.9-4.9A

no load at 14.4V

- Stall current: 130A at

14.4V (motor mfr spec)

- Motor Stall torque:

0.980Nm - 139 oz-in at 14.4V

- Peak Efficiency: ~75%

peak for motor (mfr spec) not including gearbox

Drawings etc.

Magnum775 Details

The Magnum775 includes a planetary gearbox with a 20:1

reduction ratio. This ratio gives approximately 700 RPM output speed at

low load at 14.4V. A heavy steel ring gear supports the steel planet

gears riding on hardened steel pins. Note the final stage gears are

twice as thick as the first stage gears. This helps the Magnum775 to

handle the high torque produced by the 775 motor at heavy loads. The

3" long 0.5" diameter output shaft is supported by dual

high-quality sealed ball bearings. As with all gearbox shafts a heavy

load or high shock loads on an unsupported shaft can exceed the

strength of the structure. For the most robust design support the outer

end of the shaft with a ball bearing.

Magnum775 gears

The Magnum775 is assembled with and mounted to the motor

by high quality socket head bolts. No soft phillips

head screws to strip here!

Magnum775 ring gear and motor mouting

details

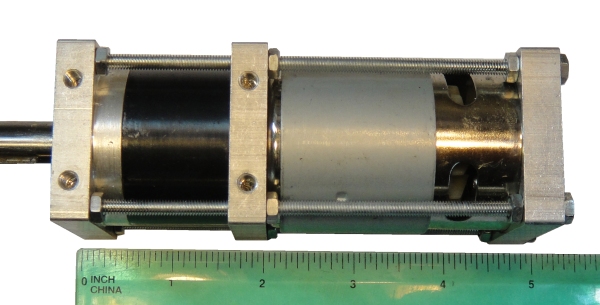

While the Magnum775 may seem lengthy but in fact it is

just under 5" from the front of the gearbox to the back of the

motor. This is actually shorter than many power drill gearmotor combinations with the added strength and convienence of the mounting flanges.

The shaft diameter of the motor pinion is 5mm. This allows

other motors with a 5mm shaft to be used assuming the mounting holes

match. Other makers of 775 sized motors offer compatible motors

allowing for upgrades or different voltage ratings. Please verify the

motor dimensions and mounting configuration.

The Magnum775 is quite compact

The Magnum775 may be mounted to the target application via

the 10-32 mounting bolts to the edgees or face

of the gearbox. A clamp style mount may also be used around the the motor can. If the gearbox is mounted securely

it is not normally necessary to support the motor can but for

high-vibration or shock applications supporting the motor along with

the gearbox is recommended.

Check the Web store for details

on prices and special offers.

Back to

top

|